Better UV Solutions!Avant UV Coatings is the premiere distributor for Clean Armor Products. We are the ONLY distributor that supports our customers with in house experienced finishers. Clean Armor was built by finishers for finishers! musical instruments-wood-metal-plastic-resurfacing and more! FASTER

TWO MINUTE CURE TIME

Clean Armor’s coating system is UVA-LED cured on demand in mere minutes. Instead of waiting hours or days for the curing process, you can cure our coating at any time, within minutes, using an LED UV curing light.

STRONGER

SUPERIOR PERFORMANCE

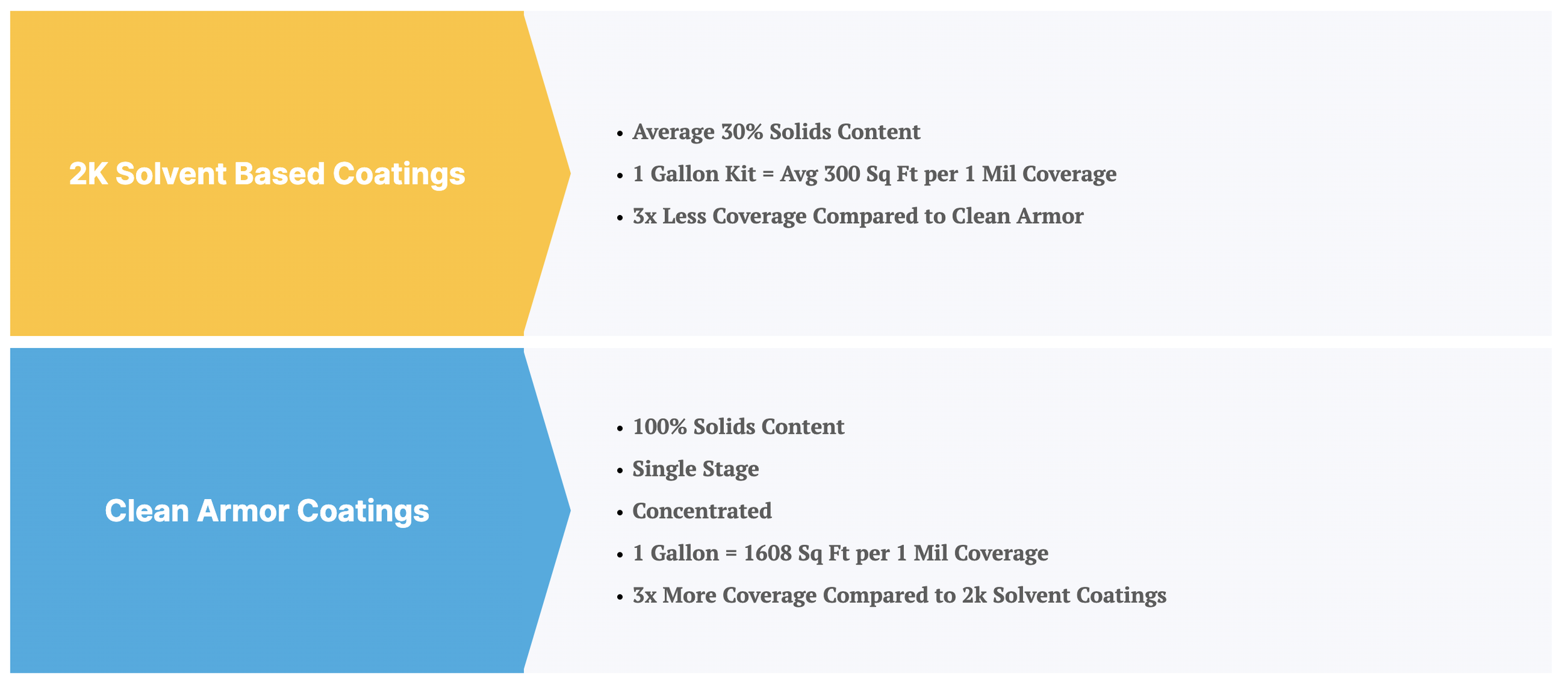

Clean Armor’s patented polymer coating system redefines the way coating’s are created. Yellowing and cracking are a thing of the past, as the coating system is 100% solids, non shrinking, UV protected, and highly resistant to damage.

CLEANER

COMPLIANT

Clean Armor has been designed from the ground up to be ZERO VOC, HAPs free and no hazardous waste. Not only exceeding state, regulatory and industry standards for safety and emissions, but going above and beyond in both performance and sustainability.

Complete cure in minutes

Clean Armor’s patented coating systems will provide you with fast finish times without compromising quality. Turning slow throughput curing from days into minutes- driving increased profitability and faster delivery times.

Eliminate your expensive and high energy burning curing steps and time consuming throughput bottlenecks that are costing you a fortune. Take advantage of the affordable and efficient low energy UVA-LED lighting system utilizing the safest range in the UV spectrum.

Fully cures within several minutes when exposed to low energy UVA-LED lighting utilizing the safest range in the UV spectrum. Even direct sunlight will provide a very fast complete cure!

Zero VOC/HAPs Free

Clean Armor’s patented coatings systems have a low carbon footprint providing you with cost savings while supporting a good environmental posture.

There is no hazardous disposal requirement for our coatings. Just cure any unused product and follow your state and local waste disposal ordinances for non-hazardous material.

No expensive emissions control equipment that is needed for solvent based or even compliant VOC products.

Our coating systems will provide you with air quality improvements as they have zero Volatile Organic Compounds (VOC), zero Hazardous Air Pollutants (HAP).

Environmentally friendly finishe provides you with a regulatory compliant solutions you can use in shop and manufacturing and onsite uses. Clean Armor is safer for end users, as it does not have any dangerous off gassing, improving indoor air quality.

Equipment cleans up easily with isopropyl alcohol and human skin contact exposure cleans up with soap and water. It doesn't get any simpler and cleaner than that!

Classical Instrument coatings from Clean Armor are the best choice for all musical instruments for tone and esthetics.

Non-shrinking 100% Solids Coating

Clean Armor’s patented coating systems enables each formulation to meet a broad range of specifications to address:

Surface hardness and flexibility

Scratch and abrasion resistance

Chemical, weathering, and aging

Provides a lasting water clear appearance, that will not yellow or lose gloss retention with age, and will lock in your final finish well beyond the performance of any existing compliant coatings.

Clean Armor coatings create superior mechanical adhesion to even the most challenging sealers, primers, color coats, pre-finished surfaces, existing base layers, and a wide variety of substrates.

With 100% solids materials, you can create build coats quickly with no shrinking. Get to your desired mil thicknesses in record time with no compromise!

Classical Instrument coatings from Clean Armor are the best choice for all musical instruments for tone and esthetics.